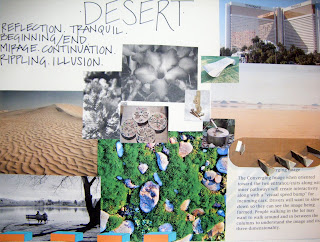

The very first picture is a collaboration of point words that our group came up with, so that we could use them to channel into our concepts. Some of the point words are no longer relevant to what we are doing currently. However, all of the words are apart of our thought process as a group and got us to the point we are at now.

The next picture is of our converging image idea. The main point for this is for it to work as a visual speed bump. We would use our ripple texture to create a sand dune image that would be visually completed as you pass by or drive by the island. And parts of the complete image are on separate parts on each platform(there are four platforms). And we all decided as a group that we wanted to do something that worked with vertical objects. So we came up with the platforms...Then the issue became,"How many should we have?" So finally we all concurred that four would be a good number because it wouldn't make the island to busy but it was enough that you could gather the image and was the right number to create interaction.

The next picture is of the rippling in the sand dunes within the desert. We decided that this would be a good texture to incorporate within our concrete objects. Because it reflects the desert but is still suttle and not to overwhelming.

This is of our group parti. Some of our initial plans were to create a water catcher, use mosaics, and incorporate a desert rose within our island as well. We wanted the water catcher to incorporate water some how. However, the issue arose of there not being anyone to keep it clean and the water would become stagnant. And then within the center of our four platforms we had decided that since we could not do the water catcher that we needed something in the center, so we devised a way to create a desert rose, and then we were going to cast it and mosaic it with glass. Our idea was that it would create a mirage effect when the light would hit the glass. However, we finally came to the epiphany that we do not have to have anything in the center. So we refined our ideas a lot. And so our design plan now is to have the four platforms and orient them diagonally towards the building so people are directed to the building. And we also have the rippling texture was over all of the platforms.

Again in these pictures we are working on our molds and platforms.

Again in these pictures we are working on our molds and platforms.

Pictured above are Chey & Kristina sanding down the final, dry and casted molds for presentation. The square square model had zebra like stripes that needed to have foam and concrete pieces removed from each of them. Due to the pine needle and Ginko leaf aggregate, the sanding removed parts of the exposed aggregate.

Pictured above are Chey & Kristina sanding down the final, dry and casted molds for presentation. The square square model had zebra like stripes that needed to have foam and concrete pieces removed from each of them. Due to the pine needle and Ginko leaf aggregate, the sanding removed parts of the exposed aggregate.

Phillip thought that he could maybe make a sphere in two halfs rather then one, so he purchased two red collinders and duck-taped the outside holes so he could pour the concrete into the new mold. He was successful in creating a sphere with two forms but the proportions of the sphere to the island and the rest of the artifacts proved to be way to small to be used in the overall composition.

Phillip thought that he could maybe make a sphere in two halfs rather then one, so he purchased two red collinders and duck-taped the outside holes so he could pour the concrete into the new mold. He was successful in creating a sphere with two forms but the proportions of the sphere to the island and the rest of the artifacts proved to be way to small to be used in the overall composition.

Stepping Stone/ Pathway Group

Stepping Stone/ Pathway Group

To create the specific design in the surface of our concrete stepping stones we cut out cardboard shapes of the negative spaces in order to get the desired effect needed to keep with the circle theme.

To create the specific design in the surface of our concrete stepping stones we cut out cardboard shapes of the negative spaces in order to get the desired effect needed to keep with the circle theme.